TEMA & HTRI Heat Exchanger Design & Cost Saving Management Training Course

Consultant/Trainer: Bert Boxma

The course provides in-depth practical understanding of major proven heat exchanger technologies and “state of art” fouling mitigation technologies. Pro’s and Con’s of several heat exchanger types are presented explained with life operational examples. This course provides a good mix of theory and common practices using highly interactive case studies where attendees are encouraged to use in-house heat exchanger type selection software and rigorous design/rating world-class software from HTRI.

Participants

This Petrogenium course can be tailored for awareness/inexperienced staff, for intermediate and for experienced personnel. Furthermore the course can be customized for a specific refinery, plant or unit. The option for post-course consultancy/help-desk support is also available.

Participants could include a wide range of Technical Professionals but will greatly benefit:

Participants could include a wide range of Technical Professionals but will greatly benefit:

- Engineers in disciplines Process, Mechanical, Project acting as specialist or generalist

- Design Specialist in heat exchanger to extend their knowledge HTRI specific

- Engineers in various disciplines; Maintenance, Turn-Around, & Cost Estimating

Learning Objectives

By the end of this course, participants will be able to perform or become:

- Proper Heat Exchanger Selection

- Heat Exchanger sizing

- Active Communicator during Meetings with Vendors

- Better observer during final inspection of heat exchangers

- Clear understanding of HTRI results

Programme

Day 1 – Shell and tubulars

Day 2 – Shell & Tubulars Advanced Technologies

Day 3 – Vibration Analysis and HTRI / TEMA Case Studies

Day 4 – Air Cooled & Compact Heat Exchangers

Day 5 – HTRI Thermal Design Aspects Condensers& Reboilers

- Historical & Market Aspects

- Basic Heat Transfer

- Mean Temperature Difference & Thermal Efficiency

- Fundamentals of Stream Analysis

- TEMA Nomenclature & Selection

- Shell, Bundle, Baffle and Tube type Selection

Day 2 – Shell & Tubulars Advanced Technologies

- Fouling Mitigation Technologies

- High Pressure Breech Lock Closure type

- Texas Tower, Helitower, Helixchanger, Helifin, Helitrans

- Tube Insert Technologies

- Low-fin, High-flux, Corrugated and Twisted Tube applications and examples

Day 3 – Vibration Analysis and HTRI / TEMA Case Studies

- Tube Vibration and FIV Prevention Technologies

- Case Study Selection of TEMA type

- HTRI Case study

Day 4 – Air Cooled & Compact Heat Exchangers

- Air Cooled & Economizer Type

- Double Pipe, Hairpin

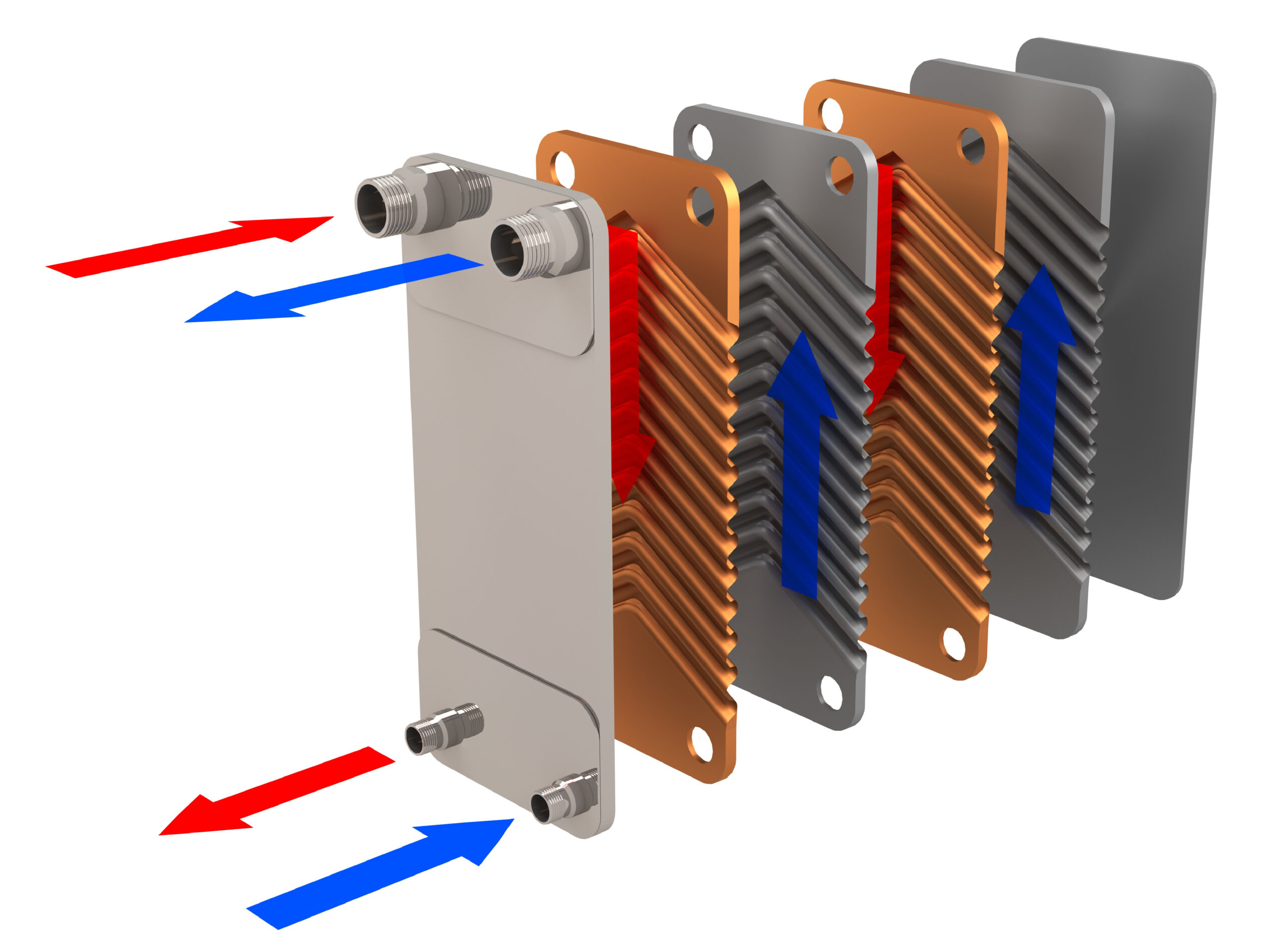

- Plate & Frame, Spiral Plate & Spiral Coil

- Welded Plate (Printed Circuit, Packinox, Brazed Aluminum)

- Submerged & Waterbath Type

- Open Rack Vaporizer

- Case Studies on Selection

Day 5 – HTRI Thermal Design Aspects Condensers& Reboilers

- Practical Aspects of Condenser Design (Reflux, Vent, Shellside versus Tubeside)

- Practical Aspects of Reboiler Design (Thermosyphon, Kettle, Falling Film)